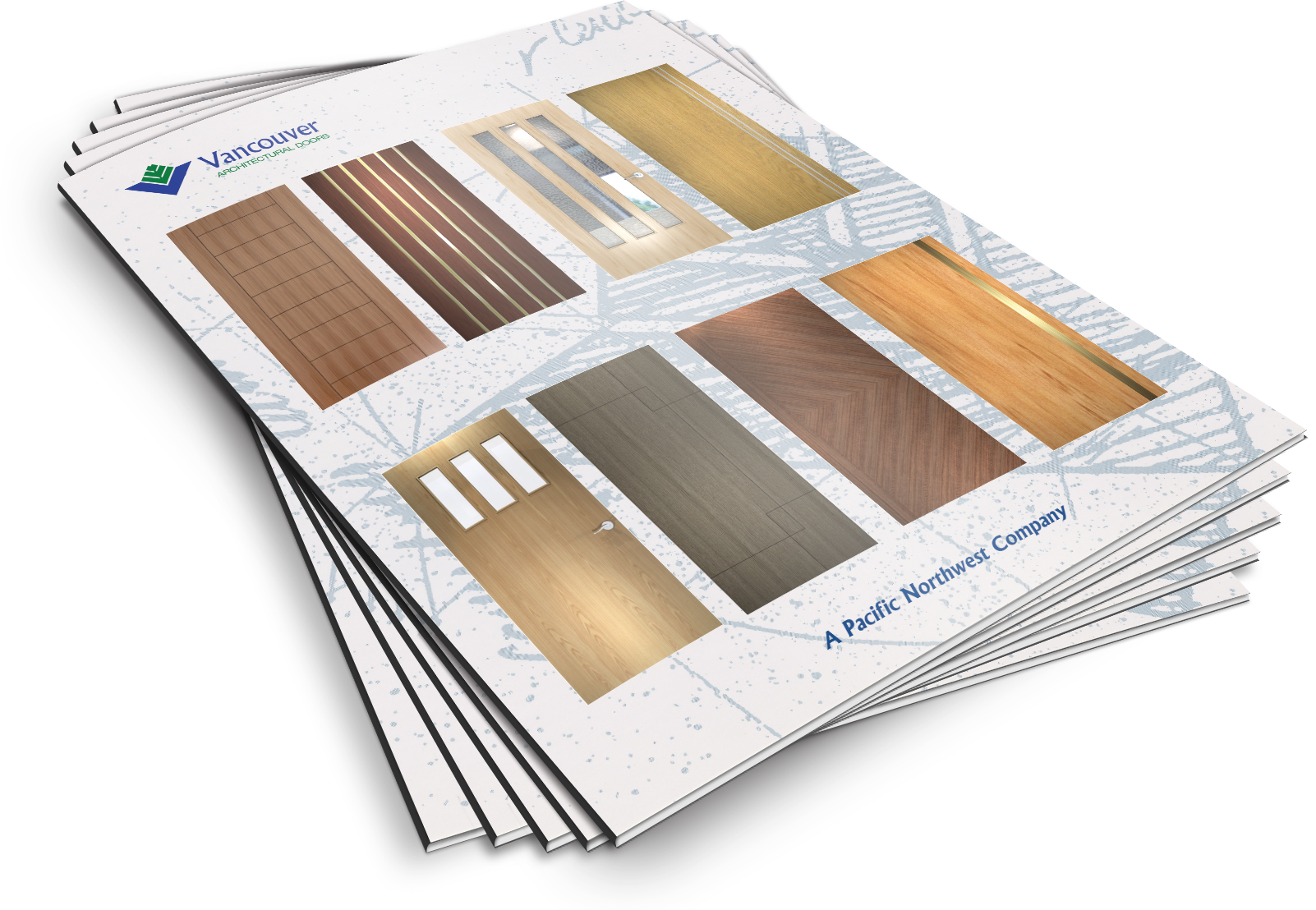

Solid Core Doors

Written by: Vancouver Door Company

Solid core doors are utilized for various applications ranging from Architectural, commercial to even residential. Not all residential solid core doors are exterior or entry doors. In many cases people prefer to have solid core interior doors due to the sound dampening and insulating qualities that a normal interior hollow core door does not provide.

The term solid core is just what it states “a solid core” but it is a generic statement in itself as solid core refers to many different types of cores. Usually when specifying a solid core door it means any other core that is not hollow core. Hollow core doors are not really hollow but have a paper or cardboard type core laid out in a “honey-comb” or grid type configuration. Some may even have a foam core that can also be found in hollow metal doors.

All manufacturers construct a typical door in the same manner with the core being the base that is framed with rails at the top and bottom and two vertical stiles, which make up the sub door. There are two typical methods to building this sub door, one is a loose lay method and one, which actually bonds or glues the stiles and rails to the core. The latter of the two is the preferred method for most architectural grade doors and provides a very durable product for heavy and extra heavy usage. Door skins (different subject matter) are typically about an 1/8″ thick overall including the backer and outer veneer that are glued and pressed to the sub door by either a hot or cold press for a given period of time.

Core types for “Solid” core doors;

Particle Core (PC) – Produced from a coarse sawdust material that is denser at the surface than at the center. This allows for a better surfacing and screw holding. LD-1 core is most common but an LD-2 core can be specified. The LD-2 is a denser and heavier core than LD-1 eliminating the need for hardware blocking that is recommended for most particle core doors.

Staved Lumber Core (SLC) – These cores are produced from small blocks of wood, which are butt jointed and glued together. Each block of wood (generally pine) must maintain a specific dimensional tolerance before it can be produced into one core. This would be utilized more for an exterior type application.

Structural Composite Lumber Core (SCLC) – These were introduced to the market just a few years ago and are produced from flakes or large chips layered in different orientation when pressed together to achieve a very strong and stable finished product. These are used in several applications including but not limited to exterior doors and doors that require a full vision lite or glazed panel.

Agri-Fiber Core (AC) – Produced and similar to particle cores in their appearance. The base material for these cores is wheat or rice that can be combined with other fiber type materials. These are typically specified for their environmental or “green” qualities for LEED type projects. They are a Rapidly Renewable material, not a forest product as are the cores described above.

Mineral Core (MC) – These cores are produced by a limited number of manufacturers and the materials used to produce them are proprietary to those manufacturers. They are used in wood doors requiring a fire rating of 45 to 90 minutes. Blocking with a denser material similar to the core for attaching hardware is highly recommended for these types of products.

Sound Transmission Class core (STC) – These cores are engineered and very specific to the ratings for which they are specified. Each STC rated core may be constructed differently to achieve the rating it is tested for and is also proprietary to each manufacturer.

Bullet Resistant core (BR) – These types of cores can vary in thickness which gives it its ballistic rating and is usually sandwiched between two other thinner pieces of different core types (usually particle core) to get the overall door thickness specified IE: 1-3/4″

There are variable construction types that can utilize the cores outlined above to gain certain qualities such as lead lined or X-Ray doors and electro-shielding for instance but, just about all doors produced will utilize one of these cores.

So next time you request a solid core door it would be beneficial to both you and the manufacturer to know what type of “Solid Core” door you are in need of based on its intended usage.

For more information on architectural wood doors, contact Vancouver Door Company at:

CONTACT INFORMATION

Address: 203 5th St. N.W.

Puyallup, WA 98371

Mailing: P.O. Box 1418

Puyallup, WA 98371

Local Phone: 253.845.9581

Toll Free: 800.999.3667

Fax: 253.845.3364

General Email: vancdoor@vancouverdoorco.com

Sales Email: sales@vancouverdoorco.com

Yes it is true we are not located in any city with the name Vancouver in it.

We are just south of Seattle, WA in a city called Puyallup (Pu-all-up)